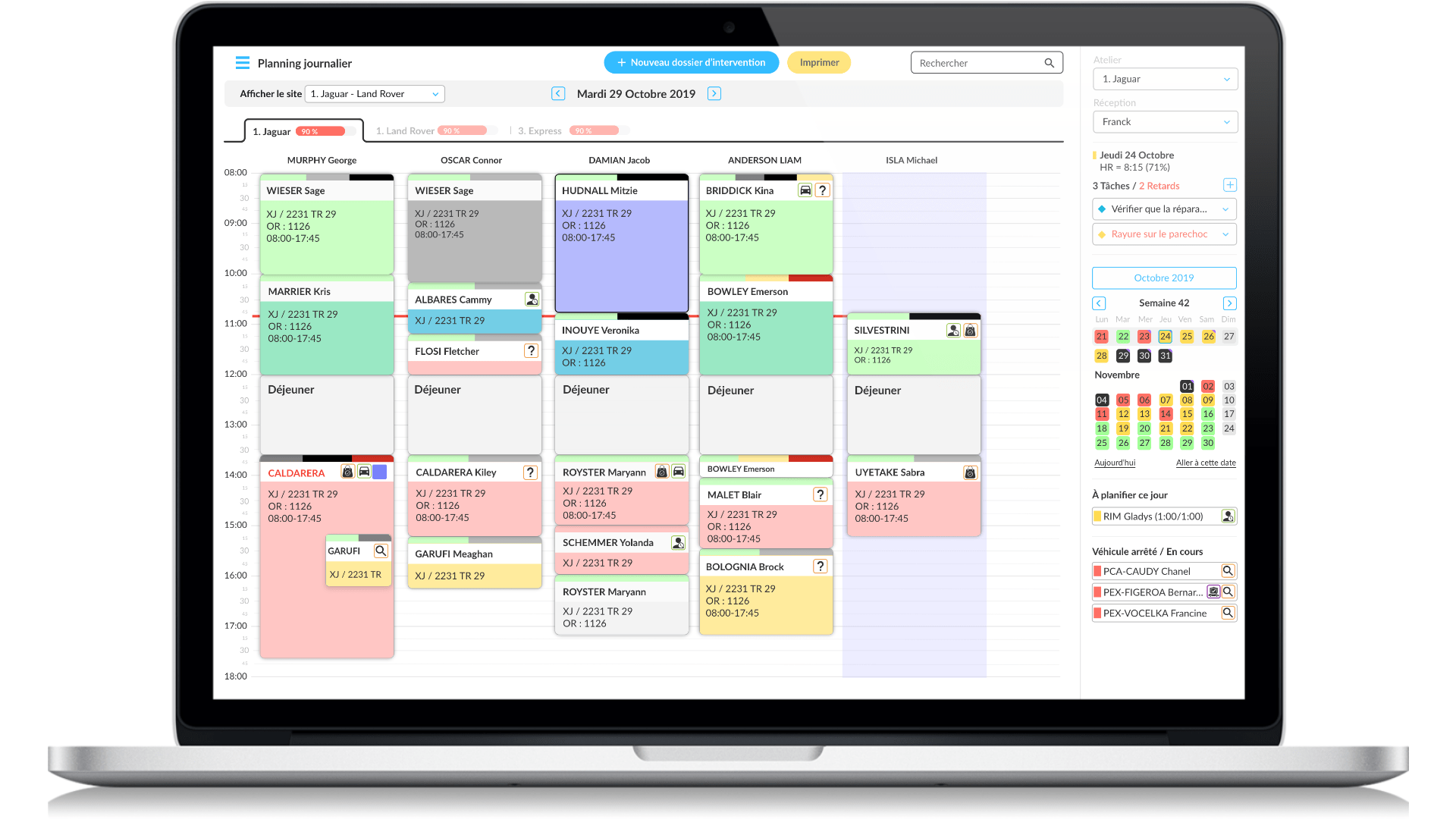

All flows automatically centralised in a single tool

Shorter lead times

Connectivity for all the factory’s IT systems

A fast-changing context

As demand for reconditioned vehicles continues to grow, major groups have created their own labels as a strategic priority,

with quality commitments that require uniform standards to be applied.

In this increasingly professionalised market, groups need to control lead times and costs and to offer an identical level of finish at all their sites.

The arrival of UV centers with new priorities

Originating across the Atlantic, reconditioning centers have now sprung up to serve the European markets. They are designed to manage and control all the issues that arise in vehicle preparation, including the reconditioning of used vehicles.

The cost to the dealership of immobilising a UV amounts to an average of €16 a day, so it’s a race against time to achieve the fastest and most efficient turnaround, including transport to and from the center.

Transforming a vehicle reconditioning center into a UV remarketing factory

Like a digital nervous system, MecaPlanning Factory analyses, manages and prioritises tasks to continuously optimise both production and administration. This completely innovative tool interfaces with all the factory’s systems and adapts to all its processes to deliver a digital control room that can track all the stages of vehicle preparation, synchronising the activities of everyone involved.

MecaPlanning Factory automates every stage of the reconditioning chain, from registering the vehicle in the dealership’s UV management software and generating the factory transport order, to publishing advertisements on sales websites and returning the vehicle to the dealership.

Managing NVs and UVs alike

As well as processing UVs, MecaPlanning Factory can also manage the preparation of new vehicles, controlling the two separate flows simultaneously and with a high level of flexibility.

Impressive results

A study of a European group using the software concluded that MecaPlanning Factory had cut lead times by 75%, resulting in a 10-day cycle rather than 40. Beyond the immediate saving on storage costs, this allowed the group to offer its customers a much wider range of UVs.

MecaPlanning Factory cuts vehicle reconditioning costs by almost 25%, increasing dealership profitability and significantly reducing returns under warranty.

Discover the related features

The associated features allow you to customise the MecaPlanning solution.

You can therefore work with a solution that is entirely adapted to your activity.

Connectivity to all the essential services.

All the services in the processing chain are integrated, from cosmetic repairs to dynamic vehicle testing.

No limits on flow types

No limits on flow types (used vehicles for private individuals and dealers, new vehicles), with checks for anomalies.

Allocation of tasks to bodywork technicians and mechanics

Close cooperation between roles to guarantee smooth operation and reduce lead times.

Discover the related features

The associated features allow you to customise the MecaPlanning solution. The associated features allow you to customise the MecaPlanning solution.

Online appointment booking

3Dsoft was a pioneer in this area, going beyond web forms and callback requests to allow appointments to be made in full via the dealership or manufacturer’s website or via a QR code. This takes place in real time at any time, with no need for human intervention. This smart system takes the workshop’s actual workload into account, predicting accurately how long the operation will take and when the vehicle will be available.

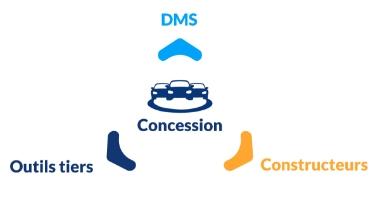

Connectivity with your environment

MecaPlanning can interface with DMS software, manufacturers’ extranets and other partners for a complete, scalable custom ecosystem.

Find out more

Download the documentation and make an appointment in just a few clicks to discover MecaPlanning Factory!

Discover our products

The digital platform for streamlined after-sales management.

Industrial-scale processes for new and used vehicle preparation centres.

Digital after-sales management for small organisations.

Automate and optimise your bodywork flows.

The after-sales reception process revolutionized for more business.